Catalytic Air Purification (CAPS)

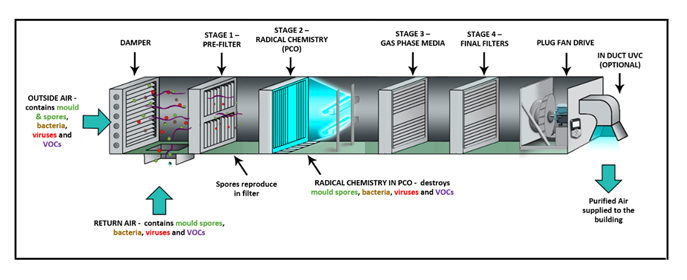

Principle Of Operation

Stage 1 – Pre-Filtration

Air entering the system passes first through a MERV 8 high-efficiency particulate filter, which captures many of the larger biological contaminants and small airborne particles such as mould spores and pollen.

Bag Pre-Filters are provided with 95% efficiency (MERV 14, EU 8), made of 100% dual layer synthetic fibres to capture finer particulates.

Stage 2 – Radical Chemistry (PCO)

Viruses, odours, VOCs and micro-organisms are exposed to a high-intensity ultraviolet light. This UV radiation penetrates micro-organisms such as fungi, bacteria and viruses and damages their DNA bonds, sterilizing them.

This air,then passes through a panel coated with titanium dioxide (TiO2), where it is subjected to ultraviolet photons, creates hydroxyl radicals. The radicals oxidize gaseous organic compounds, e.g. odours and VOCs.

Stage 3 – Gas Phase Media

The media panel is uniquely designed to continually renew itself and has a very long life of under normal use.

Media is in the form of granular pellets that are made of binders and activated alumina or other elements. Potassium permanganate is used, as it boosts the adsorption rate for a longer duration. The filtration media generally targets contaminants such as sulphur oxides, hydrocarbons, formaldehyde, organic acids, hydrogen sulphide, nitric oxide, and VOC’s.

Stage 4 – Final Filters

Final set of pleated disposable fibre matrix filters are provided with 30% efficiency (MERV 8, EU 4), to capture any left-over elements.

Premium Quality Products

with Large Sales and Service Network

Most trusted by many

recognised Brands in India

Honored with Recognitions

and Certifications

Brochures & Manuals

You can download the informational brochures or the user manuals for our products